S390 polished steel shot

S390 steel shot refers to a steel shot with a product diameter of 1.2mm. s390 can achieve good coverage in a short time. For various castings with high requirements on the surface of the workpiece, s390 steel shot has uniform hardness and good cleaning effect. ,Durable wear.

First. Introduction of S390 Steel Shot

S390 steel shot refers to a steel shot with a product diameter of 1.2mm. s390 can achieve good coverage in a short time. For various castings with high requirements on the surface of the workpiece, s390 steel shot has uniform hardness and good cleaning effect. ,Durable wear.

Second, the advantages of S390 steel shot

1. Tight organization, uniform particle size, moderate hardness, strong toughness and impact resistance.

2. Good abrasion resistance, long life, and continuous and repeatable use.

3. Uniform product, good resilience, strong adhesion and fast cleaning speed.

4. The brightness of the cleaned workpiece is large, and the processing effect is very obvious.

Third. Applicable equipment types for S390 steel shot

Pavement shot blasting machine, bridge shot blasting machine, concrete shot blasting machine, bridge shot blasting machine, pavement blasting machine, angle steel shot blasting machine, hook-through shot blasting machine, stone shot blasting machine, section steel shot blasting machine, steel bottle Shot blasting machine, steel plate derusting machine, wire shot blasting machine, steel structure shot blasting machine, steel pipe shot blasting machine, steel plate shot blasting machine

Fourth, the scope of application scenarios of S390 steel shot

1. Cleaning: shot blasting, shot blasting, die castings, castings .

2. Rust removal: shot blasting, shot blasting, casting rust removal, forging rust removal, steel plate rust removal, forging rust removal, steel rust removal, H-shaped steel rust removal, steel structure rust removal.

3. Strengthening: shot peening, heat-treated parts shot peening, gear shot peening.

4. Shot peening: section steel shot peening, section steel sand blasting, ship board shot blasting, steel plate shot peening, steel shot peening.

5. Shot blasting: steel plate shot blasting, steel shot blasting, profile steel shot blasting.

6. Sand blasting: sand blasting treatment.

7. Cast steel shot pretreatment: pretreatment for painting, pretreatment for painting, surface pretreatment, shipboard pretreatment, section steel pretreatment, steel pretreatment, steel plate pretreatment, steel structure pretreatment.

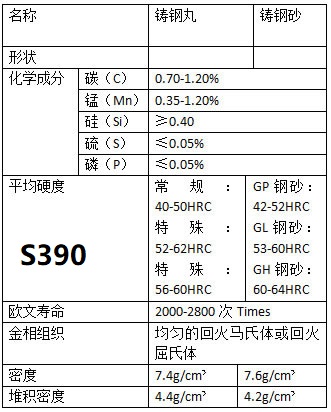

Five, S390 steel shot composition element table

NINGBO TENGYANG IMP & EXP CO.,LTD.

Contact person: Leader wang

wechat:0086 13306656100

phone:0086 574 88117909

Email:info@tengyangexport.com

Address: 3-3,NO.51, BUILDING 12,XINTIANDI EAST,YINZHOU,NINGBO,ZHEJIANG,CHINA

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Leader Wang

Phone: 0086 13306656100

Tel: 0086 574 88117909

Email: info@tengyangexport.com

Add: 3-3,NO.51, BUILDING 12,XINTIANDI EAST,YINZHOU,NINGBO,ZHEJIANG,CHINA

Tengyang

Tengyang