Titanium alloy, titanium flange bolts, hexagonal bolts, titanium screws, customized processing

Titanium alloy, titanium flange bolts, hexagonal bolts, titanium screws, customized processing

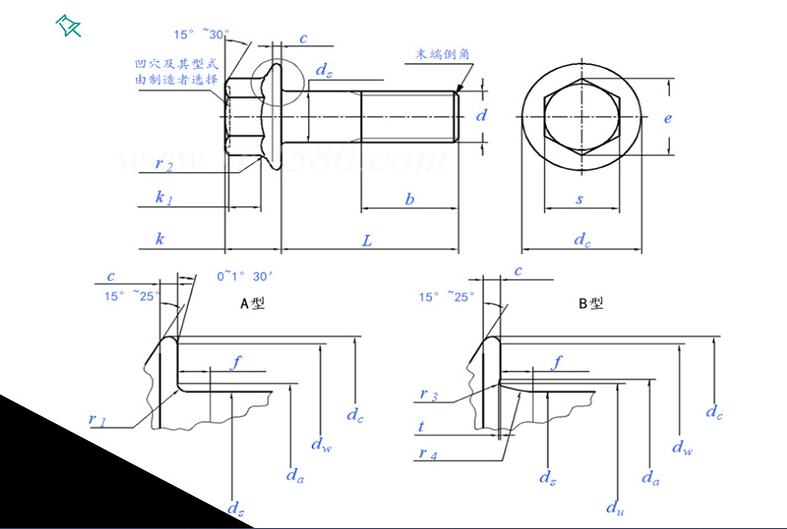

Product Name: Hexagonal Head Flange Bolt

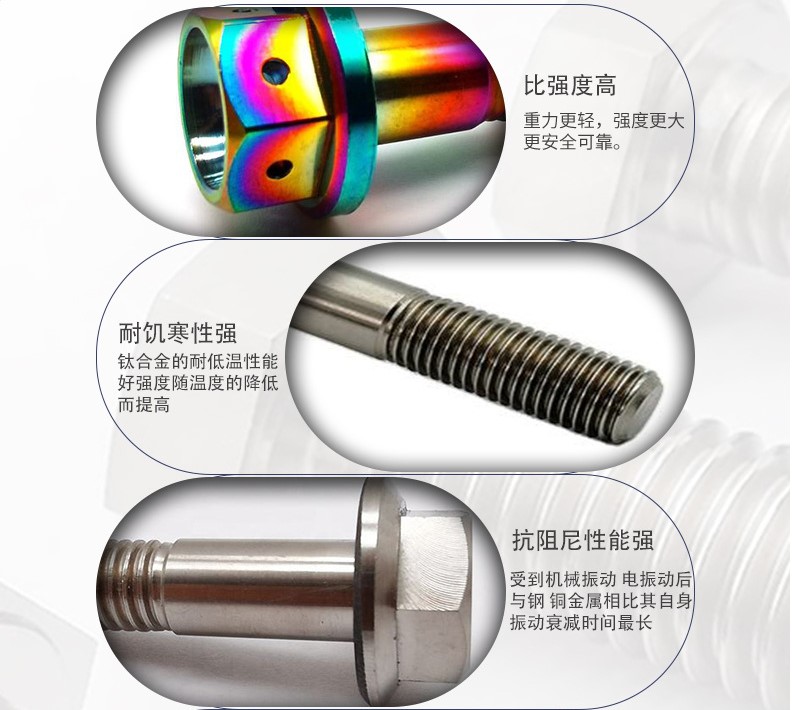

Material: Titanium and Titanium Alloy

Model: M5-M16

Length: 3mm-60mm

Density: 4.51 grams per cubic centimeter

Color: Titanium primary color, green, blue, gold, purple, rainbow color, etc

Technology: Numerical Control Machining

Contact: Leader Wang

Phone: 13306656100

Tel: 0086 0 13306656100

Email: leader@tengyangexport.com

Add: Ningbo,China